Pneumatic Staple Gun Maintenance & Trouble Shooting

Antonia MarinoA well-maintained pneumatic stapler rarely malfunctions. To avoid performance problems here are the four most important tasks to ensure you have many years of trouble-free stapling.

- Keep your gun well lubricated with 1-2 drops of oil per 1000 staples.

- Adjust the PSI pressure to suit to hardness of the wood, but keep within the specified psi range.

- If a staple becomes jammed stop shooting immediately and remove the staple by removing the faceplate.

- Make sure water in your air compressor's tank is routinely drained.

Trouble shooting

The two main causes of performance problems are lack of lubrication and incorrect PSI pressure.

Staplegun is not working.

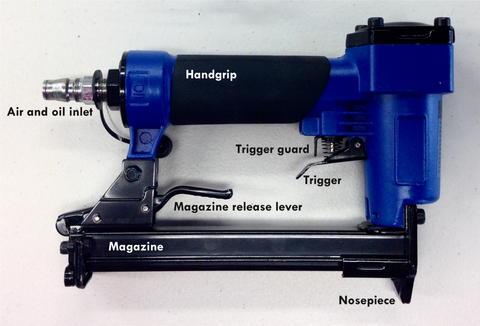

- Check if there are staples in the magazine.

- Make sure the staples you are using is the right size.

- Disable the trigger lock.

- Make sure no staples are stuck in the nose piece.

- Ensure the air hose is connected to compressor.

- Ensure the compressor is turned on and that the air tank is filled.

- Check the compressor's pressure settings and increase them if necessary.

- Make sure the staple gun is oiled.

Staple is jammed in nose piece.

- Remove the nose plate and remove the staple.

- Ensure the staple has not caused any damage.

- Ensure the tongue is straight and aligned and the nose plate has been properly replaced.

Staples keep jamming

- Lack of lubrication.

- Wrong PSI pressure.

- Nose plate not installed correctly or screws loose.

- Partial staple still stuck.

- Dirt or grease buildup.

- Damaged or bent tongue/driver.

- Damaged or bent guides.

- Not enough staples in magazine.

- Worn or damaged magazine pusher spring.

- Poor quality, rusty or dirty staples.

Staples are not penetrating the wood completely

- Low PSI pressure setting.

- Lack of lubrication.

- Damaged or bent tongue/driver

- Surface is too hard.

Staples firing too deep

- Reduce PSI pressure setting.

Skipping or mis-firing

- Lack of lubrication.

- Wrong PSI pressure setting.

- Leak in hose or fitting.

- Damage caused by moisture.

- Damage caused by jammed staple.

- Wrong size or poor quality staples.

- Magazine and/or staples are dirty.

- Magazine is loose.

- Worn or damaged magazine pusher spring.

The tongue/driver does not retract after firing

- Lack of lubrication.

- PSI pressure setting too low.

- Jammed staple.

- Dirt or grease buildup.

- Damaged or bent tongue/driver.

- Worn out seals.

Oil is coming out of the nose piece

- Reduce the amount of oil used for lubrication

Water is coming out of the nose piece

- Drain water from the air compressor tank.

Double firing

- Pressing the trigger too slowly.

- Pressing the trigger too fast.

- Not holding the staple gun firmly onto the surface.